Steel is often described as the backbone of industry, underpinning everything from infrastructure and construction to manufacturing and defense. Nations that produce their own steel not only strengthen their economic resilience but also create pathways toward sustained industrial growth. Pakistan, with its growing economy and ambitious infrastructure goals, must prioritize the development of a robust domestic steel industry to ensure self-sufficiency, economic stability, and employment growth.

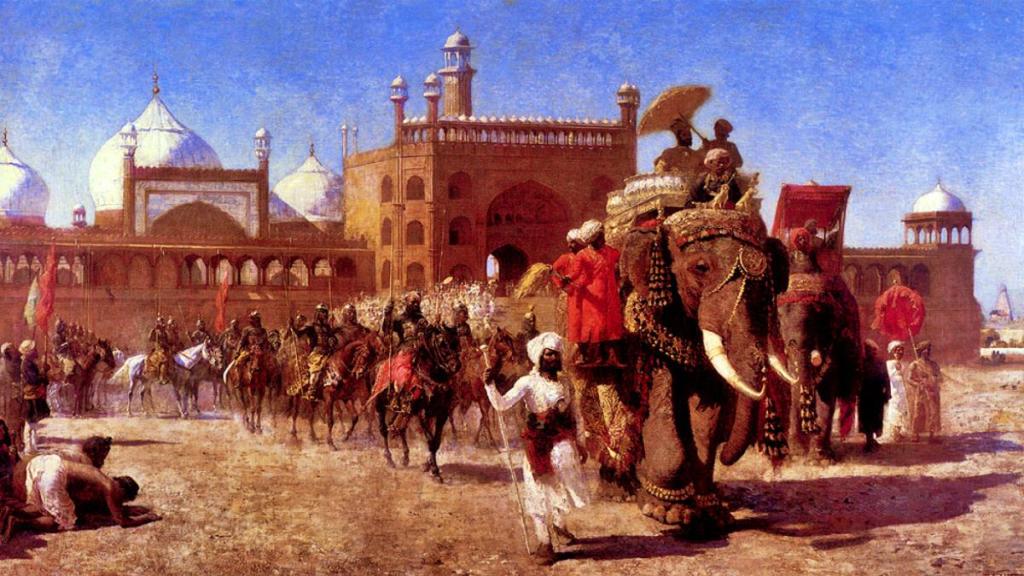

Historically, the regions within present-day Pakistan were renowned for their advanced metalworking and steel production capabilities, especially during the Mughal Empire. Mughal artisans developed sophisticated techniques to produce high-quality steel, particularly wootz steel, widely recognized for its strength, flexibility, and distinctive patterns. The steel from this region was highly prized and exported globally, significantly influencing metalworking practices and weapon production internationally. This legacy underscores Pakistan’s inherent capability to excel in modern steel manufacturing, building upon deep historical expertise and tradition.

Looking internationally, nations such as China, South Korea, and Japan demonstrate clearly how critical domestic steel production can be to broader industrial success. These countries built their economic strength on the foundation of steel manufacturing, facilitating rapid expansion in infrastructure, urbanization, and industrial diversification. For example, China’s steel industry, producing over one billion metric tons annually, has been instrumental in its infrastructural and economic advancements. South Korea’s steel giant POSCO, producing approximately 40 million metric tons annually, has similarly supported extensive industrial growth and technological innovation.

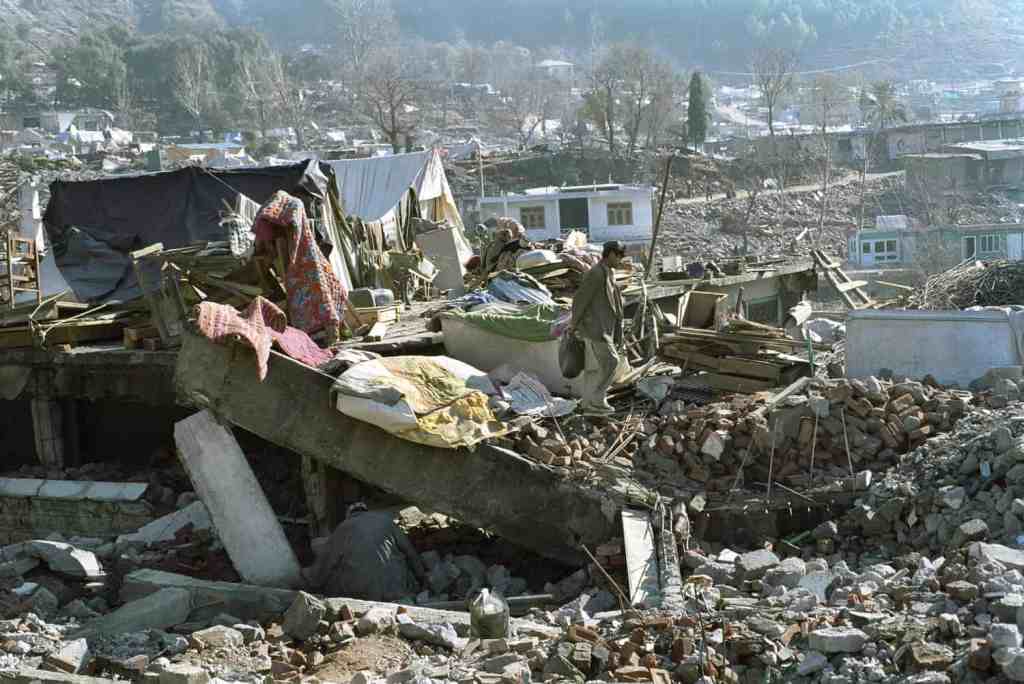

For Pakistan, investing in domestic steel mills is not merely about economic patriotism; it is a strategic necessity. Currently, Pakistan’s steel production stands at roughly 4.1 million metric tons annually, insufficient to meet the domestic demand of over 7 million metric tons, resulting in significant reliance on costly imports. Developing a strong domestic steel industry would substantially reduce import dependency, conserve foreign exchange reserves, and safeguard against global market volatility.

Moreover, a thriving domestic steel industry would create high-quality jobs across the entire value chain, from raw material extraction and processing to the manufacturing and distribution of finished steel products. These positions would be predominantly skilled, stable, and well-compensated, lifting many families from poverty and contributing positively to national economic growth.

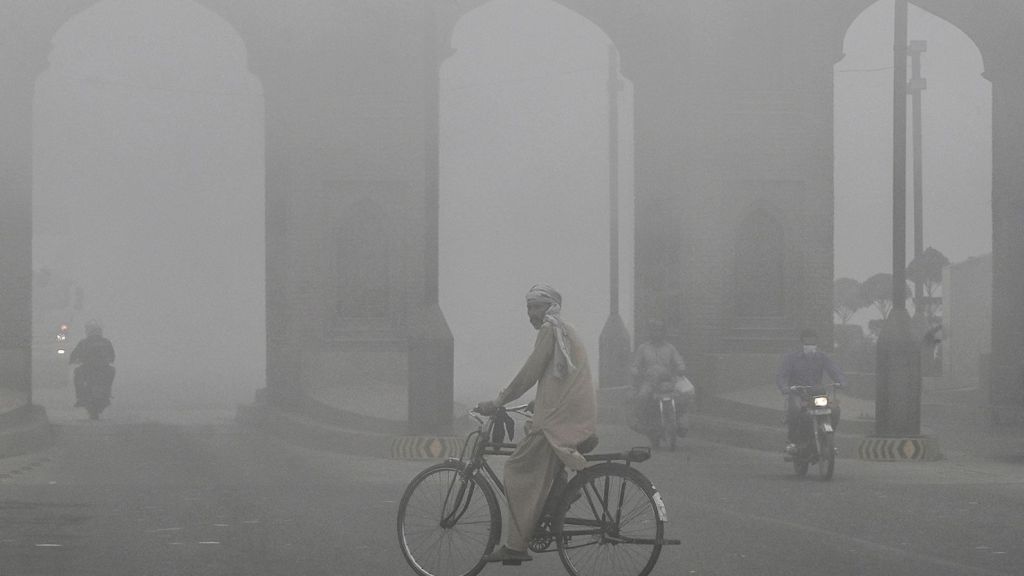

Pakistani construction projects, infrastructure initiatives, and manufacturing operations should prioritize using locally produced steel. This approach would stimulate economic growth, encourage technological advancement within the steel sector, and foster a cycle of innovation and continuous improvement. Expanding domestic steel production capabilities can lead to higher production standards, better technological infrastructure, and improved global competitiveness.

Pakistan’s steel exports hold significant potential as a driver for economic stimulation due to the country’s competitive advantage in labor costs. Lower labor expenses allow Pakistan to produce high-quality steel at more attractive prices, making it highly competitive in the global marketplace. By developing robust export strategies, Pakistan can not only increase its steel industry revenues but also enhance its international trade profile.

Furthermore, the China-Pakistan Economic Corridor (CPEC) offers Pakistan an unparalleled opportunity to collaborate with China, the world’s leading steel producer. Through this strategic partnership, Pakistan can benefit substantially from China’s institutional knowledge, advanced technology, and developmental experience. Joint ventures and knowledge-sharing initiatives under CPEC can facilitate substantial improvements in Pakistan’s steel production capacity, efficiency, and global competitiveness, ultimately fostering long-term industrial growth and economic stability.

To achieve these strategic objectives, Pakistan should undertake several actionable steps. Firstly, significant investments must be made in expanding existing steel mills and establishing new ones equipped with modern technology. Secondly, targeted policy reforms, including “five-year” style plans for steel producers, should be introduced to encourage domestic production and utilize whatever current infrastructure exists. Thirdly, comprehensive training programs must be developed to build a skilled workforce that can efficiently operate modern steel manufacturing plants. Fourthly, strategic partnerships and joint ventures with international steel producers, particularly through CPEC, should be prioritized to transfer technology, expertise, and managerial best practices. Lastly, the government must ensure the provision of reliable infrastructure, including energy supply and transportation networks, to support and sustain the growth of the steel industry. Implementing these measures will ensure Pakistan establishes a robust, internationally competitive steel industry capable of driving sustained economic growth and national development.

Steel should be forged in house. A country such as Pakistan should not be importing steel when it has the potential to produce high quality steel within it’s borders.